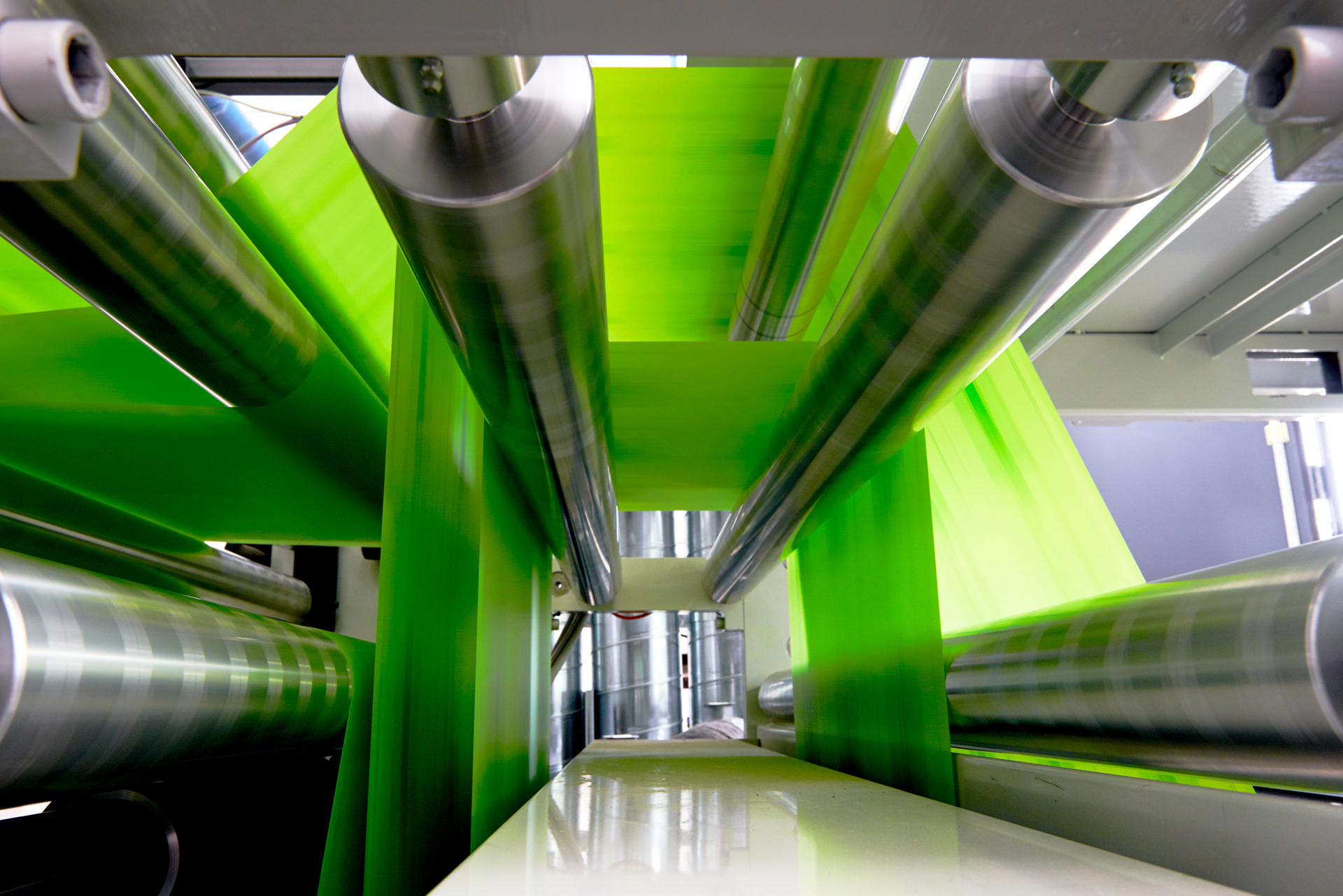

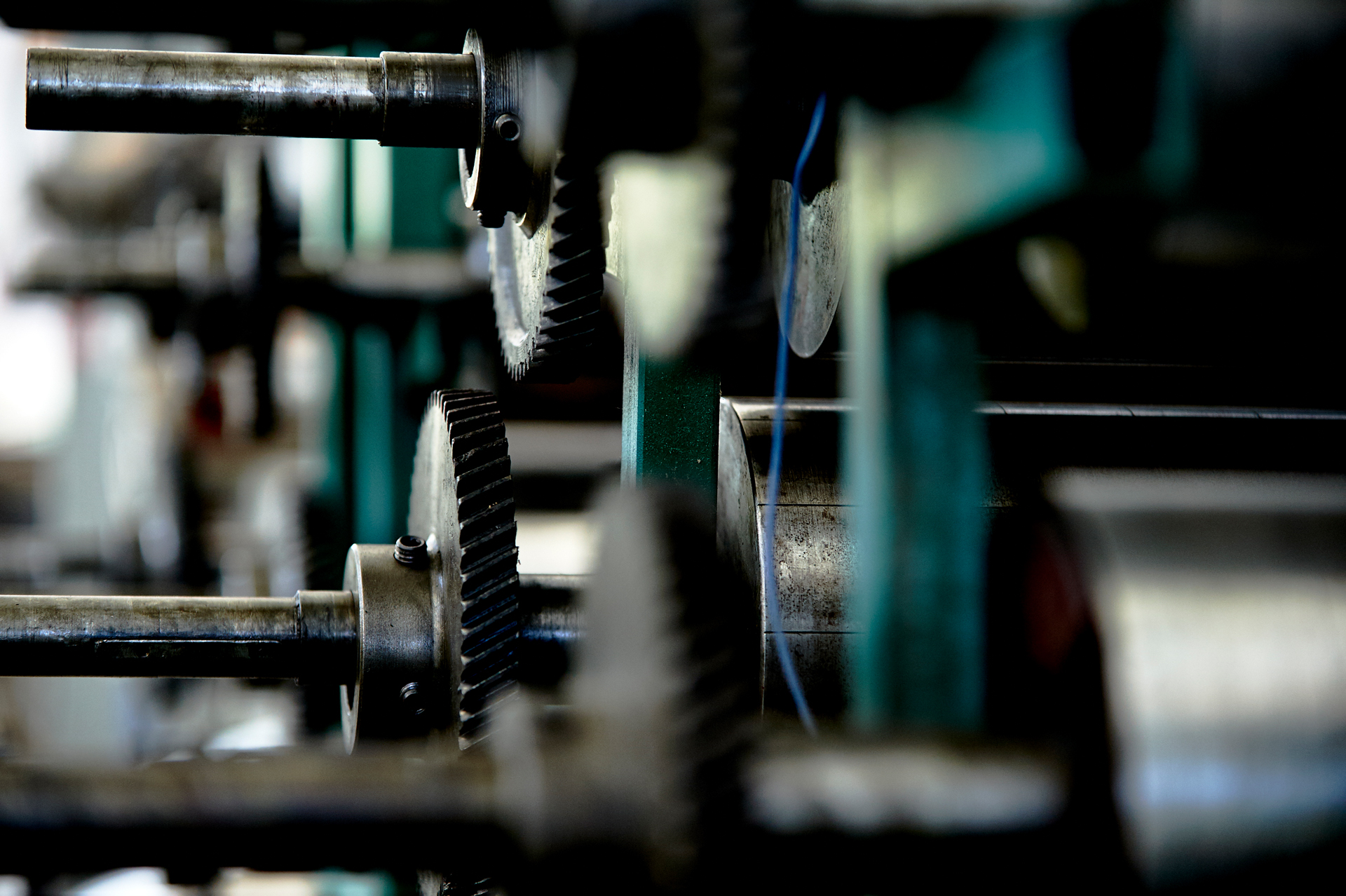

EXTRUSION

Basiliotti offers its 5 extrusion lines for the creation of products based on the needs of each customer, collaborating closely with them in the selection of materials and the type of process most suitable for the optimal success of the project.